The Nitty-Gritty of Dust Control

23 September 2016 - Dust Control Efficiency, mobile dust monitoring -

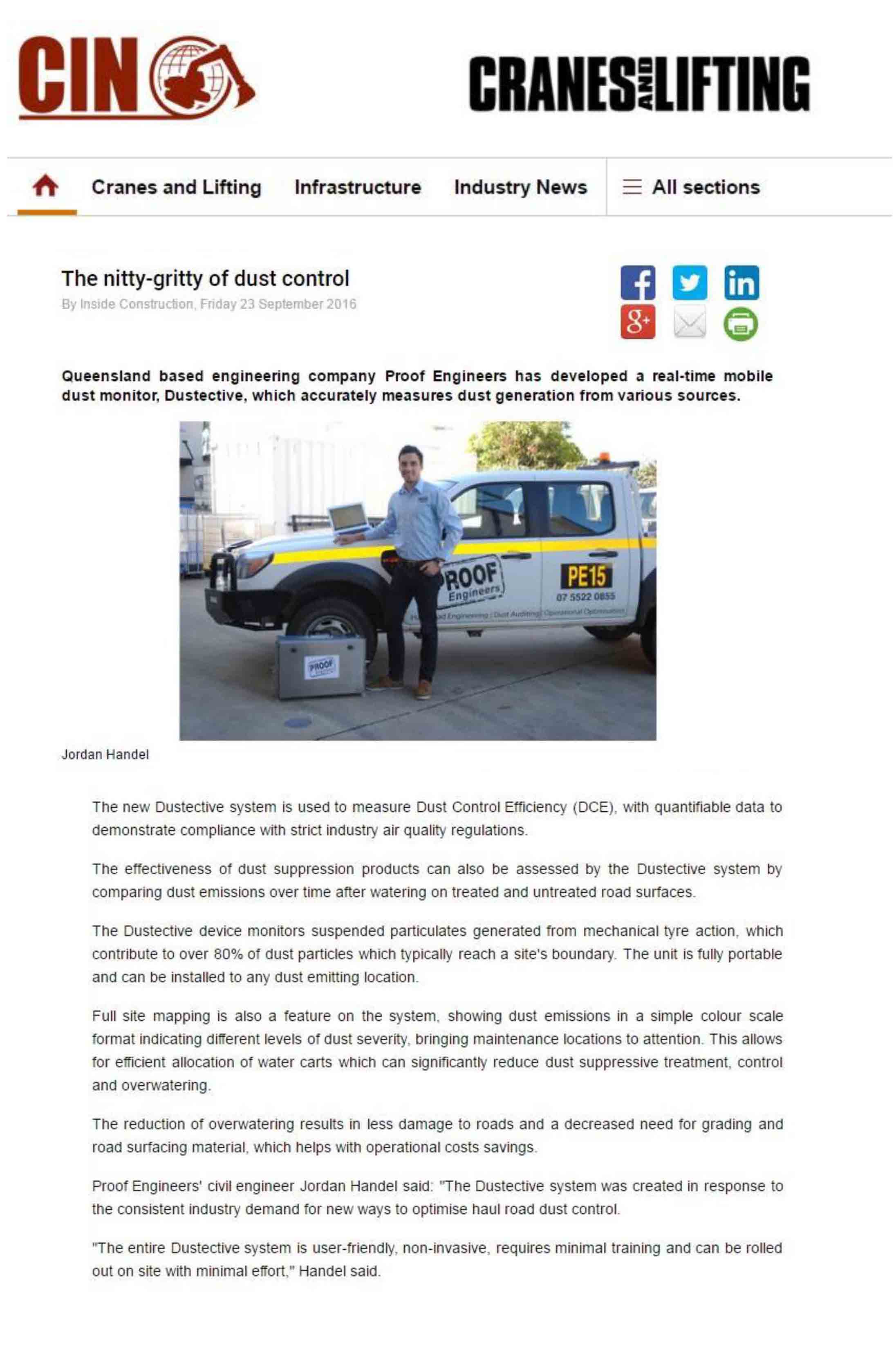

Queensland based engineering company Proof Engineers has developed a real-time mobile dust monitor, Dustective, which accurately measures dust generation from various sources.

The new Dustective system is used to measure Dust Control Efficiency (DCE), with quantifiable data to demonstrate compliance with strict industry air quality regulations.

The effectiveness of dust suppression products can also be assessed by the Dustective system by comparing dust emissions over time after watering on treated and untreated road surfaces.

The Dustective device monitors suspended particulates generated from mechanical tyre action, which contribute to over 80% of dust particles which typically reach a site's boundary. The unit is fully portable and can be installed to any dust emitting location.

Full site mapping is also a feature on the system, showing dust emissions in a simple colour scale format indicating different levels of dust severity, bringing maintenance locations to attention. This allows for efficient allocation of water carts which can significantly reduce dust suppressive treatment, control and overwatering.

The reduction of overwatering results in less damage to roads and a decreased need for grading and road surfacing material, which helps with operational costs savings.

Proof Engineers' civil engineer Jordan Handel said: "The Dustective system was created in response to the consistent industry demand for new ways to optimise haul road dust control.

"The entire Dustective system is user-friendly, non-invasive, requires minimal training and can be rolled out on site with minimal effort," Handel said.